Comprehensive Manufacturing

Specializing in machine manufacturing, fixture and apparatus production, and custom part fabrication, they offer three-dimensional design capabilities to handle diverse, client-specific projects.

Diverse Solutions in Industry

he company offers services in various areas, including Design, Machining, Maintenance, Pneumatic-Hydaulic Systems, Autmation and PLC Systems, Molds and Press Process

Commitment to Quality

We prioritize customer satisfaction through a quality policy centered on reliability, technological advancement, and cost-effectiveness, striving to build trust and continuously improve their processes and services.

Brush Less Car Wash Technology

MARVEL CARWASH WDR with important innovations to improve your business and increase your competitiveness.

The FULL model touchless automatic car wash machine offers you the best solutions in terms of technology, reliability and cost. This system is designed to speed up the washing process without contact (brushless) and not to compromise on washing quality while doing this.

System stages include subframe & side running board washing, brushless chemical spraying, high-pressure washing, waterfall type foam laying, gloss finish, air drying and hot-dip galvanized steel construction materials required for installation.

washing programs

PROGRAM 1:BRUSHLESS CHEMICAL SPRAYING

HIGH PRESSURE WASHING

PROGRAM 2:BOTTOM CHASSIS & SIDE RUNNING BOARD WASH

BRUSHLESS CHEMICAL SPRAYING

HIGH PRESSURE WASHING

FOAM LAYING (WATERFALL TYPE)

HIGH PRESSURE WASHING (RINSING)

PROGRAM 3:BOTTOM CHASSIS & SIDE RUNNING BOARD WASH

BRUSHLESS CHEMICAL SPRAYING

HIGH PRESSURE WASHING

FOAM LAYING (WATERFALL TYPE)

HIGH PRESSURE WASHING (RINSING)

POLISH (LIQUID WAX) APPLICATION

DRYING

Note: Programs can be customized due to your plan

TECHNICAL SPECIFICATIONS

| Feature | Unit | Marvel Car Wash WDR |

| Max. Machine Width | cm | 390 |

| Max. Machine Height | cm | 330 |

| Max. Machine Length | cm | 835 |

| Max. Car Wash – Drying Height | cm | 205 |

| Max. Car Wash Width | cm | 220 |

| Total Installed Power of the Machine | kW | 40.5 |

| Washing Board Power | kW | 23.5 |

| Drying Board power | kW | 17 |

| Air Pressure | bar | 6 |

| Water Pressure | bar | 6 |

| Washing Water Consumption | L/min | 150 |

| Subframe Washing Water Consumption | L/v-avg | 45 |

| 360 Swivel Arm Quantity | Custom | 1 |

| Number of Wash Arm Nozzles | Custom | 18 |

| Number of Subframe & Running Boards Washer | Custom | 16 |

| Debi Pump | L/min | 150 |

| Pump Pressure | bar | 100 |

| Number of Car Wash | v/avg | 10 – 25 |

FOAM LAYING SYSTEM (WATERFALL TYPE)

By applying foam laying on the vehicle, the WALL WASHER color LED light illuminates the solution during application, providing a unique and enjoyable customer experience.

SECURITY SYSTEM – PHOTOCELL

If the system determines that someone has entered the wash, it stops the machine from operating to prevent any accidents.

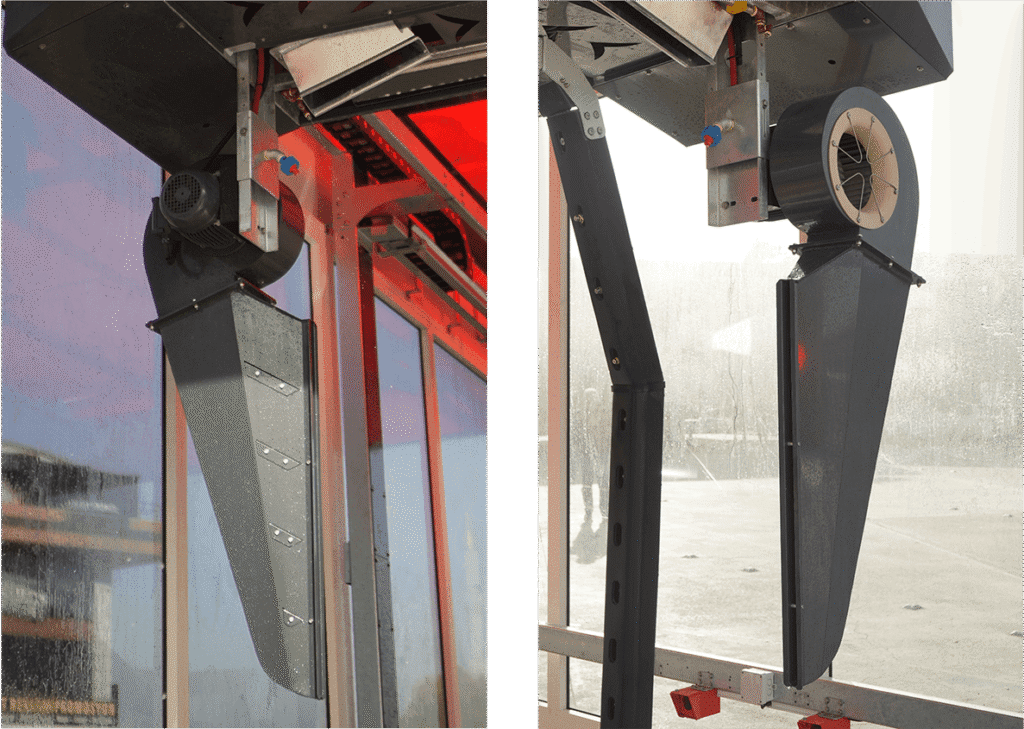

DRYING SECTION GROUP

The finishing touch that distinguishes the high-quality washing system is drying. MARVEL CARWASH WDR is equipped with a drying system that can meet your drying needs in the best way. The standard drying group consists of two fixed side drying fans and four upper fans. In the design of drying systems, we have taken care to reduce the noise problem and with the help of advanced technology, the acoustic effect is reduced while maintaining the drying quality.

MAIN MACHINE BLOCK ( 360 DEGREE ROTATING ARM )

Bridge-type automatic wash systems for buses and trucks efficiently clean large, stationary vehicles using a moving overhead bridge equipped with durable brushes, high-pressure jets, and drying mechanisms. Designed for thorough and reliable cleaning, they reach all surfaces, including challenging areas. These systems are space-saving, customizable, and ideal for fleet operations, ensuring minimal downtime.

POLISH SPRAYING SYSTEM

A special polishing polish is sprayed on the vehicle surface. It also helps drying thanks to its water-repellent feature